Horizontal End Suction Centrifugal Pump IS125-100-400 (Cast

Iron/S.S304/S.S316 )

The IS series single stage end suction centrifugal pump is the most cost-effective solution for most every day pumping

applications. End-suction pumps are available from dozens of

manufacturers, in a wide range of materials of construction, and

offered as both off-the-shelf and

custom-engineered products.

The highly efficient end suction pump is one of the simplest types

of centrifugal pump that features motor slide rails and a back pull

out design allowing for ready access and ease of maintenance. It’s

a precision-made pump suitable for electric/diesel drives, designed

to withhold temperatures of up to 105 deg.C.

Our Horizontal End Suction Centrifugal Pump is designed around a

modular concept which allows the provision of multiple hydraulics

with a small number of Power Frames. It could be manufactured

according to ANSI, ISO standards. In addition, these Power Frames

are completely interchangeable with models of other common ANSI

pump manufacturers.

All the wet part use S.S304 or S.S316, which ensure the

corrosive-proof while the pump transferring corrosive liquid, it is

wide used in drink water supply, jucie or liquor transferring,

cooling water boosting, air conditioning system, petrochemical

liquid handling, etc.

Features

Precision Cast Impeller is dynamically balanced to limit vibration

and assure smooth operation over a wide flow range. The impeller is

positively secured by a set screw and a locknut, the threads of

which are not exposed to the pumped liquid.

Flanges are in accordance with ASME B16.5 Class 300 RF standard or

600 RF optional.

Pump Casing and Cover feature metal-to-metal fit with fully

confined, controlled compression gasket to ensure proper sealing

and alignment. A double volute design is used on all large pump

sizes.

Suction Nozzle Guide Vane on larger sizes reduces inlet vortexing

and ensures uniform flow into the impeller to achieve a reliable

NPSH margin

Back Pull-Out Design simplifies maintenance as neither the motor

nor the piping is disturbed.

Renewable Casing and Impeller Wear Rings reduce maintenance costs

and keep the clearance between wear surfaces in compliance with API

610 standards.

Our spare parts are produced with the same precision as new

products. They fulfill the same criteria and get tested to meet our

client's requirements and performance range. Our objective is to

ensure that each part fits precisely and brings the pump system

performance back to as-new condition.

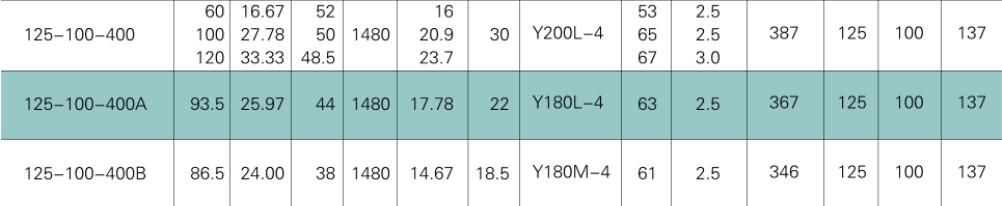

Main Performance Data

Flow: 120 - 240 m3/h

Delivery Head: 38 - 52m

Inlet/Outlet Dia.: 150/125mm

Working Pressure: ≤ 0.8Mpa

Solid Particle: ≤ 80mg/L

Liquid Temp.: 0℃ - 120℃

Model Instruction

E.G.: IS/IR/IY/IH/IHF200-150-400A

IS: Single stage end suction pump (for clean water)

IR: Single stage end suction pump (for hot water)

IY: Single stage end suction pump (for oil liquid)

IH: Single stage end suction pump (for corrosive liquid)

200: Inlet diameter is 100mm

150: Outlet diameter is 80mm

400: Rate impeller diameter is 160mm

A(B,C....): Impeller code

Applications

* Water supply

* Drainage

* Irrigation

* Air conditioning

* Fire fighting

* Condensate circulation

* Cooling services

* General industries

* Water transfer & boosting

Main Parts Configuration

The pump could be applied to transfer different kinds of liquid by

customized wet parts, here followed our recommendation of main

configuration:

| Parts Name | Clean Water | Drink Water | Hot Water | Corrosive Liquid | Acid Liquid |

| Pump Body | Cast Iron | S.S304 | Cast Steel/S.S304 | S.S304/S.S316 | Cast Iron + F46 |

| Shaft | Carbon Steel | S.S304 | S.S420/S.S304 | S.S304/S.S316 | S.S420/S.S630 |

| Shaft Sleeve | Carbon Steel | S.S304 | S.S420/S.S304 | S.S304/S.S316 | F46 |

| Impeller | Cast Iron | S.S304 | Cast Steel/S.S304 | S.S304/S.S316 | Cast Iron + F46 |

| Wearing Ring | Cast Iron | S.S304 | Cast Steel/S.S304 | S.S304/S.S316 | F46 |

| Bearing | China Make/NSK/SKF |

| Seals | Mechanical Seals |